Illinois Reuse Machineries and Industrial Equipment Newsboad > Industrial Machines

> New

> Without Warranty

> Schmidt sand blast & vacuum recovery +air dryer system

Schmidt sand blast & vacuum recovery +air dryer system

Blast Recovery System (BRS) & AirPrep Air Dryer System - "Skid mounted"

(From left to Right: Blast Pot. Filter. Air Dryer.)

The function of the BRS unit is to blast and recover abrasive media. The BRS is designed to

blast, vacuum, or blast and vacuum simultaneously. The media is contained in the pressure vessel

for blasting. After blasting, media is recovered in the media reclaimer by means of a pneumatic

vacuum system. Small particles are carried by the vacuum air stream into the dust collector. The

media and large particles (paint chips, cigarette butts, etc) drop to the bottom of the media

reclaimer. The media is reloaded at atmospheric condition from the media reclaimer into the

pressure vessel after passing through a screen.

Blast Recovery System (BRS) - * Blast Pot & Filter system

he Blast and Recovery System (BRS) uses a wide range of abrasive media to remove coatings, hazardous materials such as lead or asbestos, and other materials when cleaning steel or concrete surfaces.

This portable system is ideally suited for jobs where traditional open-air blasting is prohibited, or is not possible or practical.

high productivity systems designed for use with a wide range of abrasive media.

Perform blast and vacuum functions. The BRS can perform these tasks simultaneously,

virtually eliminating dust clouds, improving visibility, and reducing costly cleanup.

BRS systems can also perform blast and vacuum functions independently,

making them versatile and powerful tools for many blast cleaning applications.

(( pneumatic Blast & Recovery System - Abrasive Blast Recovery System other sandblaster spot blaster ))

The Schmidt BRS can blast and vacuum simultaneously, effectively eliminating offensive dust clouds, poor visibility and costly cleanup. It can also perform either feature independently. The portable system is ideally suited for jobs where traditional open-air blasting is prohibited, or is not possible or practical.

* Portable system used for lead and asbestos abatement, indoor blasting, bridge and road maintenance, building restoration and other steel and concrete cleaning applications

* Flexible system can blast and recover simultaneously or independently

* Available in 2.0, 3.5 and 6.5 cu. ft. systems with pneumatic or electric remote controls, patented Thompson Valve metering system and ComboValve blowdown system

* Cyclone has large, quick-opening access door and two-part screen with removable center for easy access

* Optional, adjustable, air wash cyclone improves abrasive cleaning

* Three-way dust collector designed for wet, dry or dry-HEPA filters

* Automatic pulse jet prevents clogging of dust filters

* Quick opening hatches make cartridges and filters easy to remove and replace

* Urethane eductor pump is available with 225, 350, 440, or 550 cfm nozzle

* Moisture separator and media vibrator ensure even flow of abrasive

Options include 3 BRS head with outer brush, remote abrasive cutoff for cleaner start/stop and reduced abrasive consumption, blast pressure regulator with gauge

http:// /dynamic/products/literature/20080603112753_BRS%20Manual%20rev%204-08.pdf

AirPrep Systems eliminate moisture problems in your abrasive blasting compressed air system. With it's innovative design, AirPrep Systems effectively provide cooler, cleaner and drier air to your blasting system with negligible drop in pressure. By reducing rusting, clogged blast pots, damp abrasives and damaged valves, you'll decrease costly downtime and increase productivity.

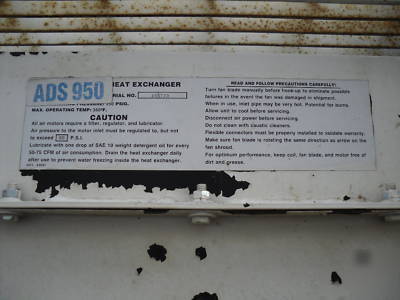

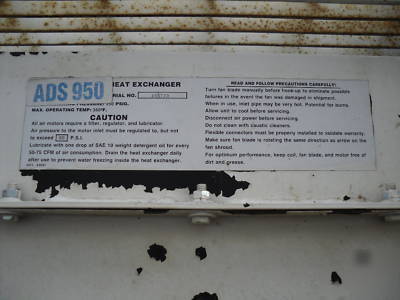

system type ( Air Dryer System - ADS 950)

* Compact, vertical air flow design

Skid mounted with forklift pockets and full load-lifting eyes for portability; yard trailer mount and custom systems are available

* Protective bar grating

* 6" x 8" inspection port

* Pneumatic fan motor includes filter, regulator, lubricator, and muffler; electric fan motors available

http:// /dynamic/manuals/20091207181423_Dryer%20rev10-07.pdf

http:// /nsbdryair-schmidt.html

pdf manuals online *

Questions Call 1-(***)-380-3922

Email: ****@gmail.com