Illinois Reuse Machineries and Industrial Equipment Newsboad > Tools

> New

> Howard rotavator gem, super gem workshop manual

Howard rotavator gem, super gem workshop manual

This is a full workshop manual for the Howard Gem mk1-V and Super Gem very clean reproduction of the original, below are some excerpts from the introduction which will tell you exactly what is covered etc.

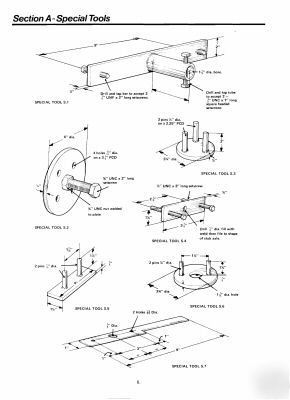

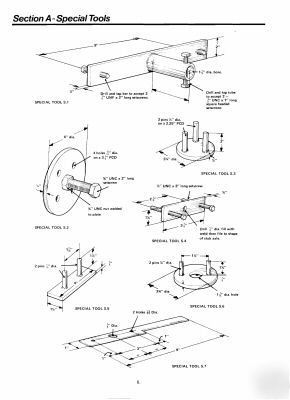

Specifications, torque loadings, special tools. A

Engine removal, clutch, clutch shaft, air cleaner. B

Main frame, handlebars, shields.

Rotor, rotor clutch, drive chain, backplate.

Lubrication, maintenance and fault finding.

This service manual has been compiled to give HOWARD Dealers and their

staff, a sequence of operations to enable the servicing and repair of a

GEM ROTAVATOR to be carried out quickly and effectively.

Because of our policy of continuous improvement, this manual should

always be used in conjunction with the latest service bulletins covering the

GEM. These service bulletins are distributed to all HOWARD horticultural

dealers when they are first printed, and back issues are available from us on

request. HOWARD GElVl service bulletins after bulletin H.63, should be

kept with this manual, and a note added to the index of each section

affected, so that an up to date record of modifications is kept.

At the start of each section, there is a list of ordinary workshop tools that

will be required when carrying out the repairs covered by that section.

Some 'special tools' may also be required, of which a complete list can be

found under 'special tools' section 'A'.

In addition to the special tools and equipment used during some repairs, a

hydraulic or hand operated fly press (of the type found in most workshops)

will be required when removing and fitting oilseals and bearings.

Before assembly of component parts, remove dirt and grease and, in the

case of new parts, remove the special rust inhibitor, otherwise the function

of the component may be restricted when in operation. When ordering

spare parts, DO NOT confuse the illustration numbers used in this manual

with the TRUE part numbers found in the official parts list, form number

The HOWARD GEM has been developed over

Since its introduction in 1942, there have been five series of GEM, each

series being an improved version of

The original GEM was fitted with 'bicycle type' handlebars, but was not

a differential or a reverse gear. Series 1 machines were

produced from serial number 101 up to machine serial number 4800, and

these machines were fitted with the HOWARD B.J. engine.

'Swinging type' handlebars and

a differential were introduced at the start

of the series II GEM, and later they were equiped with a reverse gear

operated by a lift up lever. Series II machines were produced from serial

number 4801 up to machine serial number 14784, and these machines

were fitted with the original HOWARD B.J. or

I II and IV machines overlapped. The basic machine

remained the same for both, only the engines were different.

Series I l l machines were produced from serial number 14785, and were

fitted with either the HOWARD B.J. or a J.A.P. 600cc engine. During

I II, the first series IV machines were phased in.

These machines were fitted with

a new HOWARD engine, the 180 Twin.

From machine serial number 38760 series l V machines only were produced,

but were fitted with an improved version of the twin engine-the

HOWARD 360 Twin -or alternatively a water cooled Sachs diesel engine.

Series IV machines were discontinued

at machine serial number 47066.

This is the current series of GEM, which was introduced

number 47067. Machines up to serial number 2541824 were fitted with

an up-rated version of the HOWARD 360 Twin engine, or the Sachs

diesel. From machine serial number 2541825,

been fitted in place of the twin, or from machine serial number 2571945,

an alternative diesel engine, the Hatz ES.780, has been used. An improved

version of the Hatz engine has been fitted from machine serial number

250A1021, and is designated the Hatz ES780U.

The super GEM is an up-rated version of the Series V model produced

specifically for contract work where greater strength and power are

required. Super GEM machines are fitted with either a Kohler K341 petrol